New optimised mobiles for industrial mixers reduce energy consumption

Industrials mixers are used for a wide range of applications, from simple homogenisation to the dispersion of a gas in a liquid, from dilution to complex emulsions and heat transfer.

Reducing energy consumption is a concern for all industrial sectors (pharmaceuticals, food processing, petrochemicals, water treatment, etc.) in which industrial mixers are used.

AGITEC designed and manufactured mobiles, such as the new DisGaz turbine model, whose technological advances reduce energy consumption by around 30% compared with conventional Rushton-type turbines.

ENERGY SAVINGS AT THE HEART OF R&D AT AGITEC®, MANUFACTURER OF INDUSTRIALS MIXERS

AGITEC's Research & Development department is working hard on the design of new agitator profiles. An unprecedented budget has been earmarked for this purpose. The aim is to offer agitators with optimised energy consumption. From the beginning of 2023 and in the years to come, an increasingly complete range of turbines for industrial mixers will be stamped with the Low Energy Consumption group Label.

REDUCE ENERGY CONSUMPTION WITH THE DISGAZ TURBINE FOR INDUSTRIAL MIXERS

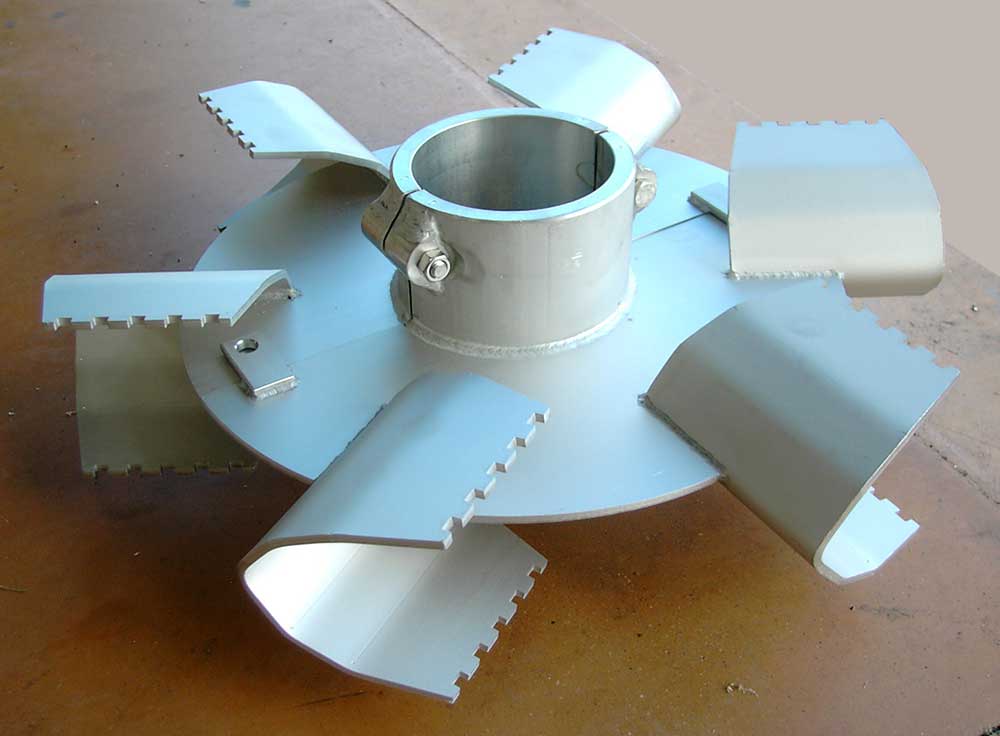

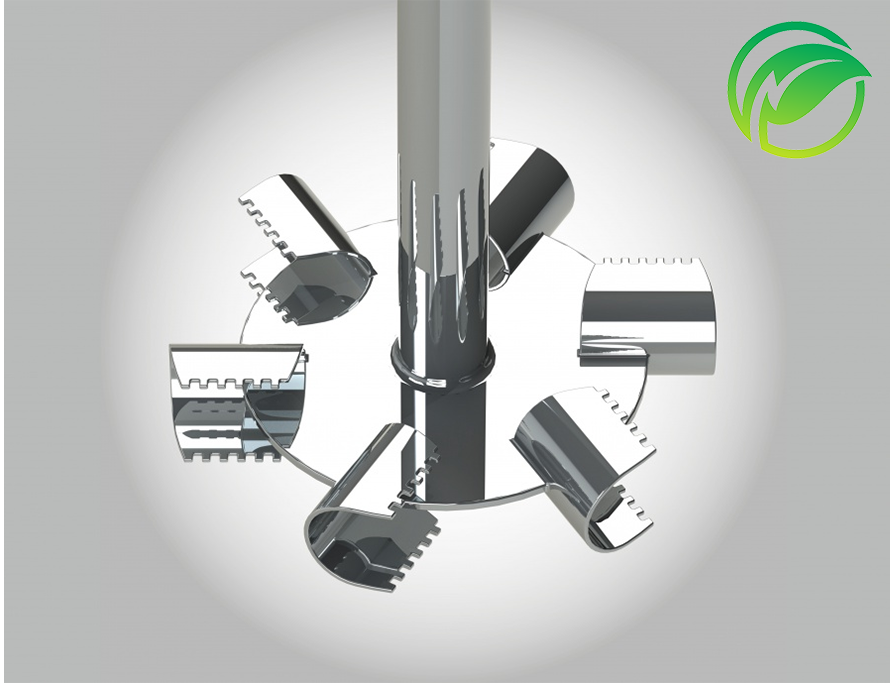

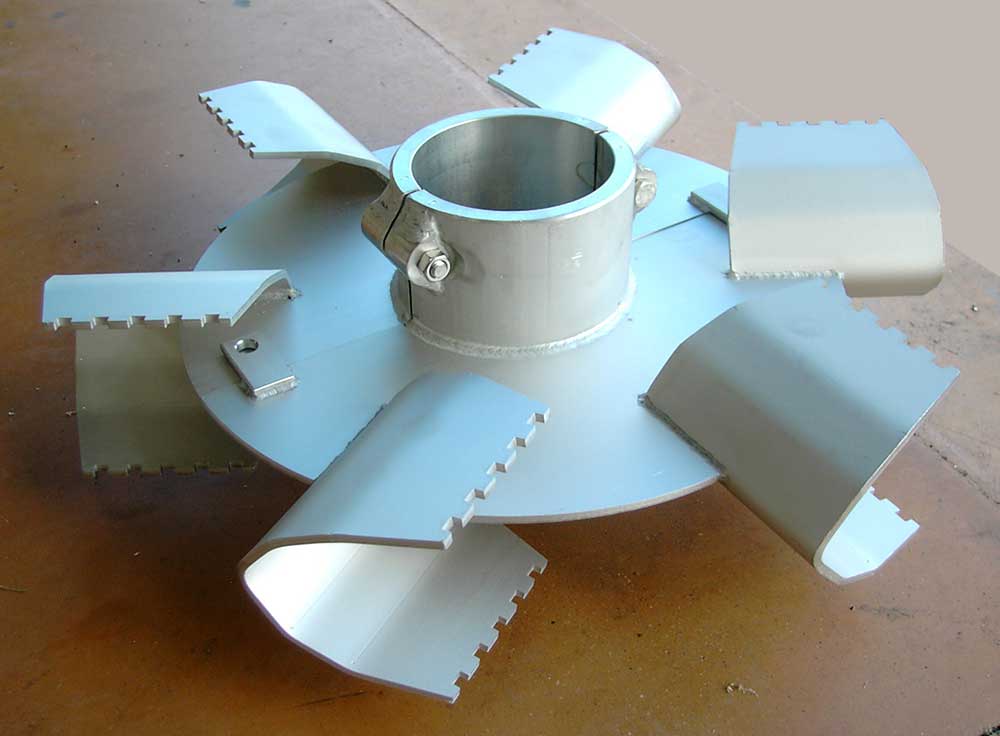

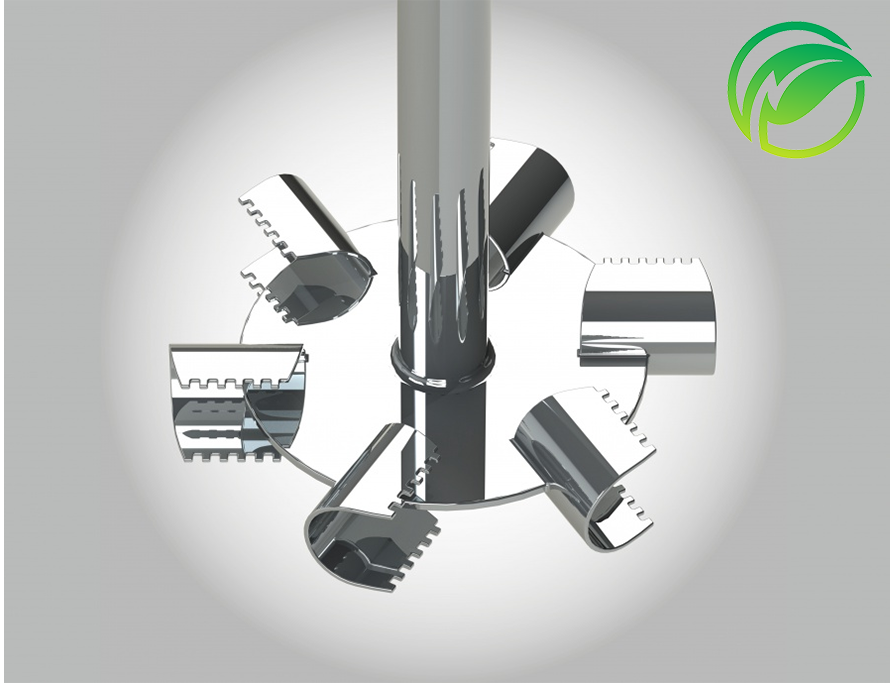

When designing the new Disgaz mobile, we sought to generate a reduction in energy consumption for the same efficiency. To achieve this, we designed a horizontal disc with 6 profiled blades to optimise the mobile's penetration of the liquid.

This particular blade profile limits the surrounding losses (initially due to a frontal attack on the liquid by a straight blade fitted to Rushton turbine). The result is a saving of around 30% with the new generation Disgaz turbine compared with a Rushton-type turbine.

The energy saving achieved retains the full efficiency of the mobile for gas/liquid dispersion operation, thanks to the combs at the end of each Disgaz blade. This mobile is the first in a range that is set to expand over the coming years.

These new developments will enable AGITEC to offer the biotechnology, food processing and pharmaceutical industries a wide range of products.

Zoom ON THE DISGAZ TURBINE

The DisGaz turbine has 6 blades. Its discs have notched blades. Its radial flow is centrifugal and horizontal. A vacuum creates the vortex. At maximum speed, a significant shearing effect can be generated.

The hight centrifugal effect of the DisGaz turbine makes it particularly suitable for gas/liquid dispersion applications. It is also suitable for stripping-type processes. It can be combined with one or more pumping impellets.

DisGaz TURBINE vs Rushton TURBINE

The special feature of the Rushton turbine, with its 6 straight blades, is that it mixes the liquid and the gas centrifuged on its disc to disperse and reduce the gas into a multitude of small bubbles of equivalent volume. The primary objective is to increase the gas/liquid exchange surface area at the same gas flow rate.

The process of dispersing gas bubbles with the Disgaz turbine differs from the Rushton in that the combs at the tip of its blades scratch the gas. The vane shape of the blades generates a significant vacuum at their back. This suction draws the gas in and forces it to pass throught the combs to be scratched. This innovative technology delivers the same gas/liquid exchange results as a Rushton, but with a significant reduction in energy consumption.

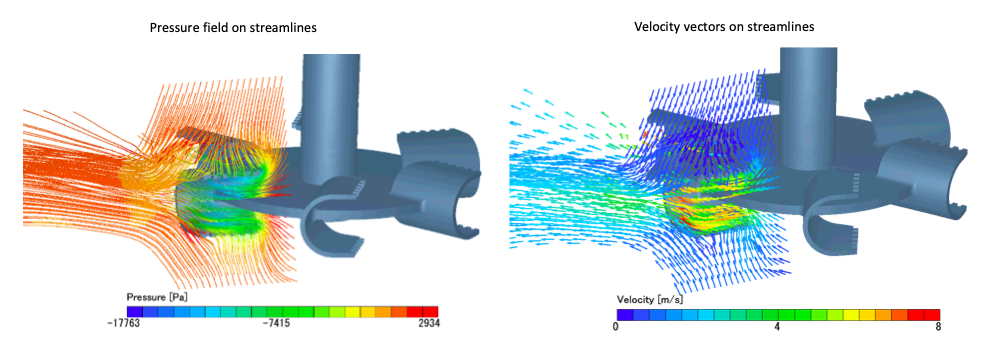

HOW THE Disgaz WORKS

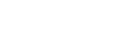

The gas bubbles to be dispersed are sheared off as they pass throught the teeth of the Disgaz blades. A vaccum is then created inside the blades, where the bubbles are sucked up before being ejected laterally thanks to a strong radial flow.

30% ENERGY SAVINGS WITH AN OPTIMISED MOBILE

The new Disgaz and its gas-scraping blades generate a negative pressure behind the combs and create an overpressure on the leading edge. Shear rates at the leading edge of the blades and at the disc are also significant with both processes, due to the yawing or scratching effect. The pressure fields of the Rushton turbine and the Disgaz remain similar.

|

|

Mobile comparison: Ruston VS Disgaz

|

| |

Rushton |

Disgaz |

| Power input (W) |

891 |

622 ≈ (-30%) |

ExAMPLE OF AN OPTIMISED INSTALLATION IN THE PHARMACEUTICAL SECTOR

For one of our customers, we supplied 10 new-generation Disgaz turbines. These mobiles installed around 30 years ago. The Disgaz mobiles are installed in 500 to 1000 m3 fermenters. These installations are powered by 1 to 3 MW (megawatt) motors. For this customer, reducing energy consumption was becoming a matter of urgency.

Fluid mechanics engineers designed several blade prototypes. Fluid modelling software calculated bothh the mechanical forces and the power consumed during gas/liquid dispersion operations. The results were compared with the hydrodynamic efficiency of each prototype. installed for more 2 years, with identical efficiency, the new Disgaz mobiles are saving around 30% in energy each year.

With the same efficiency, 30% energy savings is a real advantage for all types of industrial installations. With this first "Low Energy Consumption" mobile, gas/liquid dispersion operations are more economical. In the near future, we will be offering our customers more energ-efficient solutions for homogenisation, dilution and complex emulsion operations.