Applications > Homogenization

Homogenization is a process whose action leads to the mixing of products or liquids with each other so as to obtain a structure that is as homogeneous and regular as possible, either two liquid phases or a liquid and solid phase.

As the homogenization process is suitable for the implementation of a wide variety of mixtures from substances that may or may not be miscible with each other, combining liquid/liquid or liquid/solid and with varying degrees of viscosity and solubility, the choice of the most suitable solution is decisive for the perfect success and durability of the application envisaged.

The choice of the optimal installation not only determines whether the desired degree of homogeneity can be achieved and maintained, but also whether this can be achieved in the shortest possible time and with a perfect control of the energy consumption required to achieve it.

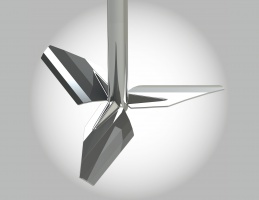

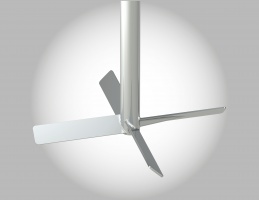

Homogenization is most often achieved by stirring on the basis of a tank stirrer installation. The different types of equipment associated with the agitator, such as turbines, propellers or anchors will be chosen according to the specific characteristics of the products or liquids to be mixed.

Thus, for products that are easily miscible with each other, homogenizers with slow rotation and equipped with non-shearing tools will be adopted, two-bladed or three-bladed propellers for homogenization applications requiring high pumping, while rotor/stator turbines will be recommended for the homogenization of tank bottoms in order to obtain the high shear necessary for good dispersion.

The homogenization process is used in all industrial sectors, but more particularly in the pharmaceutical industry where it will allow, for example, to ensure the strict respect of the proportion of active principle in a drug, or in the pigments and paints industry for which the homogenization of the mixtures represents an essential step in the final elaboration of the products.